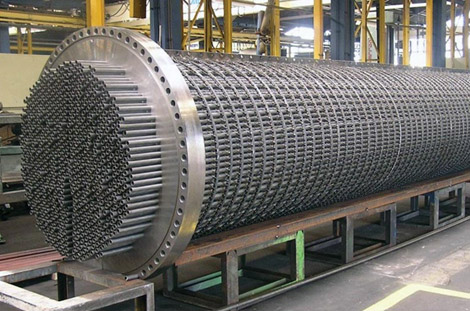

Automotive

Our products include steering columns, telescopic front forks, stabilizer bars, drive shafts, and fuel injection/suspension/braking system tubes. These tubes are designed for fatigue resistance, weldability, and dimensional precision for safety-critical subsystems and are used in all automotive applications including passenger vehicles, commercial vehicles, two- and three-wheelers, off-road equipment, and farm machinery. Together, these products cover the full spectrum of automotive requirements from mobility to heavy-duty transport.